Rheology of Gums Used in the Food and Flour Industry for "Tortillas"

University of Bucharest, Faculty of Chemistry, Department of Physical Chemistry, Elisabeta Blvd, 030018, Bucharest, Romania.

Corresponding Author E-mail: istanciu75@yahoo.com

DOI : http://dx.doi.org/10.13005/ojc/380414

Article Received on : 13 Jun 2022

Article Accepted on : 17 Aug 2022

Article Published : 24 Aug 2022

Reviewed by: Dr. Tirsoaga-Jurca Alina

Second Review by: Dr. Noureddine Ouerfelli

Final Approval by: Dr. Tanay Pramanik

Food gums are hydrophilic colloids, which due to their functional properties are used in the food industry. For non-Newtonian rubber solutions to these factors must be added the dependence between the shear stress and the shear rate. Experimental data were obtained with a Haake RV20 rotary viscometer with a con-plate system. The range of shear speeds for which the determinations were made was between 24 and 3177s-1, and the shear stresses between 2.2 and 116.9Pa.

KEYWORDS:Food Gums; Particle; Tortillas; Rheology

Download this article as:| Copy the following to cite this article: Stanciu I. Rheology of Gums Used in the Food and Flour Industry for "Tortillas". Orient J Chem 2022;38(4). |

| Copy the following to cite this URL: Stanciu I. Rheology of Gums Used in the Food and Flour Industry for "Tortillas". Orient J Chem 2022;38(4). Available from: https://bit.ly/3pHr8pH |

Introduction

Food gums are hydrophilic colloids, which due to their functional properties are used in the food industry 1-5. Their most important functional properties are: water retention capacity, decrease in evaporation rate, change in cooling rate, change in the formation of ice crystals, regulation of rheological properties, participation in chemical processes, keep insoluble particles in suspension, stabilize foams and emulsions 6-9.

Many seemingly homogeneous liquids are composed of particles with irregular shapes or inhomogeneities of the liquid phase. On the other hand, there are polymer solutions with long or curly molecular chains. At rest, all these materials are characterized by an irregular internal structure and consequently oppose the flow, having high viscosity.

This article presents the rheological behavior of food gums used in the food industry as well as flour for “tortillas”.

Material and methods

Experimental data were obtained with a Haake RV20 rotary viscometer with a cone-plate system. The range of shear speeds for which the determinations were made was between 24 and 3177s-1, and the shear stresses between 2.2 and 116.9Pa.

Results and discussion

Table 1 shows the rheological parameters for the aqueous solutions of some food gums derived from the power law.

The form of the Ostwald model or the law of power:

The expression of the law of power (relation 2) can be linearized by logarithm:

Obviously, mathematically, addiction τ = f(ln γ) is a line, from the intersection to the ordinate obtaining the value of ln K, and from the slope the value of n. This is one of the most used calculation procedures for K and n. We exemplify with the interpretation of some recent data from the literature 10, concerning rheological studies for flour from which tortilla paste is obtained. Experimental data obtained for addiction τ = f(γ) are shown in both Table 2 and Figures 1 10 and 3.

Table 1: Rheological parameters of aqueous solutions of food gums obtained from the law of power.

|

Food gum |

Concentration (%) |

Temperature (°C) |

K (Pa . sn) |

n |

|

Furcellaran |

0.8 |

25.4 |

0.49 |

0.55 |

|

|

1.2 |

24.4 |

2.82 |

0.45 |

|

|

1.6 |

24.4 |

15.1 |

0.24 |

|

Guar |

0.5 |

24.4 |

1.12 |

0.45 |

|

|

1.0 |

24.3 |

20.3 |

0.17 |

|

|

1.5 |

24.7 |

46.4 |

0.16 |

|

|

2.0 |

24.5 |

10.2 |

0.094 |

|

Xantan |

0.5 |

25.3 |

0.93 |

0.37 |

|

|

0.75 |

24.5 |

1.76 |

0.32 |

|

|

1.0 |

24.4 |

2.74 |

0.29 |

|

|

1.2 |

24.7 |

3.98 |

0.26 |

|

Figure 1: Rheological behavior of pasta obtained from “tortillas” flour: Model RSM as and Robertson and Stiff’s Model RPM as Rational Polynomial Model |

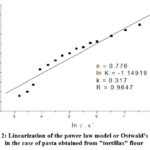

Table 2 contains in the first two columns, the experimental data obtained by the authors on a Haake RV20 rotary viscometer with a cone-plate system. The other 4 columns in the table, as well as figures 2 and 3 were obtained by us with the Origin 7.0 program, based on the data taken from Nunez-Santiago’s work [10]. With the logarithmic values of the shear stress and speed, the dependence from relation (2) was plotted in figure 2. By linear correlation (R = 0.9647) the values for n (0.776) and K (0.317) were obtained, respectively.

Table 2: Experimental values for the influence of shear rate on shear stress obtained from rheological measurements for pasta obtained from “tortillas” flour t1 and t2 are calculated values of the shear stress with the help of K and n obtained by linearization, respectively by the nonlinear regression applied to Ostwald’s model.

|

Shear rate(s-1) |

Shear stress t (Pa) |

Shear stress (Pa) |

Shear stress ln t(Pa) |

Shear stress t1 (Pa) |

Shear stress t2 (Pa) |

|

24 |

2.2 |

3.17805 |

0.78846 |

3.73 |

6.68 |

|

32 |

2.7 |

3.46574 |

0.99325 |

4.66 |

7.92 |

|

40 |

3.9 |

3.68888 |

1.36098 |

5.55 |

9.03 |

|

51 |

8.6 |

3.93183 |

2.15176 |

6.70 |

10.42 |

|

68 |

10.8 |

4.21951 |

2.37955 |

8.38 |

12.33 |

|

89 |

13.7 |

4.48864 |

2.6174 |

10.32 |

14.45 |

|

114 |

17.5 |

4.7362 |

2.8622 |

12.51 |

16.72 |

|

149 |

19.8 |

5.00395 |

2.98568 |

15.40 |

19.56 |

|

191 |

25.3 |

5.25227 |

3.2308 |

18.67 |

22.64 |

|

245 |

27.2 |

5.50126 |

3.30322 |

22.65 |

26.21 |

|

318 |

33.9 |

5.76205 |

3.52342 |

27.73 |

30.55 |

|

403 |

36.4 |

5.99894 |

3.59457 |

33.32 |

35.12 |

Because n is subunit, the paste obtained is a pseudoplastic fluid. Using the power law expression (relation 1) the values for voltage ( τ 1) in the penultimate column were calculated. It can be seen that at high shear rates there is a big difference between the experimental values (2nd column) and the calculated values (penultimate column). The same differences can be seen in the graph, as can be seen in Figures 1 and 3. This means that, for this product, the linearization of the power law does not allow obtaining correct values for K and n. The graph in Figure 2 itself confirms this conclusion. And in the original graph in the paper, figure 1, the same deviation of the calculated values of the shear stress is observed, compared to the experimental ones.

|

Figure 2: Linearization of the power law model or Ostwald’s model in the case of pasta obtained from “tortillas” flour |

Instead, by nonlinear regression and a large number of iterations, using a function identical to that of the law of power, we managed to obtain with the program Origin 7.0, more correct values, which allowed the calculated values (last column) to be closer of the experimental ones, and the calculated curve to overlap excellently (R2 = 0.9934) over the experimental rheogram (figure 2). The new values obtained for the two rheological parameters are n = 0.588 and K = 1.032 Pa. sn.

Similar correlations with ours were obtained by Nunez-Santiago and collaborators, using two other models. The first of these is the Robertson and Stiff model 11, for which the correlation factor is R2 = 0.996 and the overlap of the calculated curve over the experimental one is very good. The second model is the rational polynomial model 12. The correlation factor is R2 = 0.998 and the overlap of the calculated curve (RPM model in figure 1) over the experimental one is excellent.

Robertson and Stiff’s model [11] can be written:

Where A, C and B are parameters according to the rheological theory proposed by Robertson and Stiff.

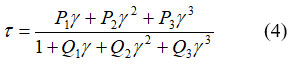

The rational polynomial model (RPM) has the form:

where P1, P2, P3, Q1, Q2 and Q3 are parameters that strongly depend on the shear rate according to the rheological theory proposed by Kumar 10-16.

|

Figure 3: Comparison of curves calculated with values obtained by linearizing Ostwald’s model (dotted curve), respectively by nonlinear regression of the same model (continuous curve) ○ – experimental points. |

Conclusions

From the obtained data it can be concluded that both food gums and pasta obtained from flour for “tortillas” have a pseudoplastic fluid behavior and follow Ostwald’s model.

Linearization of the power law model or Ostwald’s model in the case of pasta obtained from “tortillas” flour led to the following parameters: n = 0.776, lnK = -1.14919, k = 0.317 and R = 0.9647.

References

- Barak S., Mudgil D., & Taneja S., 2020, Journal of the Science of Food and Agriculture, 100(7), 2828-2835.

CrossRef - Rao M.A., & Kenny J.F., 1975, Canadian Institute of Food Science and Technology Journal, 8(3), 142-148.

CrossRef - Sánchez V.E., Bartholomai G.B., & Pilosof A.M.R., 1995, LWT-Food Science and Technology, 28(4), 380-385.

CrossRef - Qi X., Zhang M., Su T., Pan W., Tong X., Zeng Q., … & Shen J., 2020, Journal of agricultural and food chemistry, 68(12), 3770-3778.

CrossRef - Clemens R.A., & Pressman P., 2017, Nutrition Today, 52(1), 41-43.

CrossRef - Kayacier A., & Dogan M., 2006, Journal of Food engineering, 72(3), 261-265.

CrossRef - Li X., Xing Y., Sun Q., Chu L., & Xiong L., 2015, Starch‐Stärke, 67(5-6), 399-406.

CrossRef - Wallingford L., & Labuza T.P.,1983, Journal of Food Science, 48(1), 1-5.

CrossRef - Farkas E., Glicksman M., 1967, Food Technol., 21, 535-538

- Nunez-Santiago M.C., Santoyo E., Bello-Perez L.A., Santoyo-Gutierrez S., 2003, Journal of Food Engineering , 60, 55–66

CrossRef - Robertson R.E., Stiff H.A., 1976, Society of Petroleum Engineers Journal, 2, 31–37

CrossRef - Kumar A., Saboo S., Sheth S., Pilehvari A., Serth R., 2000, Chemical Engineering Communication, 183, 99–117.

CrossRef - Stanciu I., 2019, Journal of Science and Arts, 3(48), 703-708.

- Stanciu I., 2019, Journal of Science and Arts, 4(49), 938-988.

CrossRef - Stanciu I., 2011, Journal of Science and Arts, 1, 55-58.

- Stanciu I., 2018, Journal of Science and Arts, 18(2), 453-458.

This work is licensed under a Creative Commons Attribution 4.0 International License.