Adsorptive Behavior of Kaolin for Amido Black Dye in Aqueous Solution

Olushola S. Ayanda1,2, Kehinde O. Sodeinde2, P. O. Okolo2, Ayomitide A. Ajayi2, Simphiwe M. Nelana1 and Eliazer B. Naidoo1

1Department of Chemistry, Vaal University of Technology, Vanderbijlpark 1900, South Africa.

2Nanoscience Research, Department of Industrial Chemistry, Federal University Oye Ekiti, P.M.B 373, Oye Ekiti, Ekiti State, Nigeria.

Corresponding Author E-mail: osayanda@gmail.com

DOI : http://dx.doi.org/10.13005/ojc/340305

Article Received on : March 06, 2018

Article Accepted on : June 07, 2018

Article Published : 23 Jun 2018

In this study, the adsorption of amido black (AB) dye onto kaolin was investigated. The characterization of kaolin was carried out by powder x-ray diffraction (XRD), scanning electron microscopy (SEM), transmission electron microscopy (TEM), energy dispersive spectroscopy (EDS) and Fourier transform infrared spectroscopy (FTIR). Adsorption studies showed that the adsorption of AB onto kaolin increased with increasing adsorbent dosage, contact time, pH and temperature but decreased with increasing dye concentration. Equilibrium data fitted perfectly into the Langmuir and Freundlich equilibrium models, moreover, the kinetic data followed the pseudo-second order model. The adsorption process is endothermic and approximately 60.75% AB reduction was achieved when 0.75 g of kaolin was mixed with 20 mL of 40 mg/L AB for 60 min at 200 rpm. Therefore, this study shows that kaolin can be harnessed for the treatment of textile wastewater.

KEYWORDS:Adsorption; Amido Black Dye; Isotherms; kaolin; kinetics; Thermodynamics

Download this article as:| Copy the following to cite this article: Ayanda O. S, Sodeinde K. O, Okolo P. O, Ajayi A. A, Nelana S. M, Naidoo E. B. Adsorptive Behavior of Kaolin for Amido Black Dye in Aqueous Solution. Orient J Chem 2018;34(3). |

| Copy the following to cite this URL: Ayanda O. S, Sodeinde K. O, Okolo P. O, Ajayi A. A, Nelana S. M, Naidoo E. B. Adsorptive Behavior of Kaolin for Amido Black Dye in Aqueous Solution. Orient J Chem 2018;34(3). Available from: http://www.orientjchem.org/?p=46886 |

Introduction

Dyes are widely used in industries to color products and improve the products’ appearance. Wastewater from these industries constitutes a major source of water pollution in the environment.1 Most of these dyes are toxic, stable and non-biodegradable,2 and are known to cause mutagenesis, carcinogenesis, chromosomal fractures, and respiratory toxicity.2,3 Hence, there has been growing concern about dyes environmental impact and the need to develop suitable and sustainable wastewater treatment methods. Different treatment methods that have been developed over the years include adsorption, coagulation, biodegradation, ion exchange, and the advanced oxidation processes.4,5 Among these methods, adsorption process is considered more suitable in terms of simplicity, convenience and ease of operation.6 Notable adsorbents include activated carbon, oxides, alumina, silica, zeolites, etc.7 In recent years, biomass waste, fly ash, clay minerals, and agricultural wastes have also been used as cheap and efficient adsorbents for the remediation of dye wastewaters.7

Kaolin is an important clay mineral with numerous practical applications in environmental remediation, construction, pulp and paper, paint, refractories and ceramic, and plastic industries.8,9 It is well known for its good adsorption properties.10 By their different modes of formation, kaolins possess diverse compositional and physical characteristics. The dominant mineral phase is kaolinite, a 1:1 dioctahedral hydrated aluminium silicate (Al2Si2O5(OH)4) clay mineral.11,12 The other clay phases including halloysite, illite and smectite may also occur along non-clay phases, such as quartz, anatase, iron-oxides goethite and haematite depending on the origin and depositional environment.8,13 The clay mineral mostly occurs as very small (< 20 μm), crystallites with large surface areas, onto which chemical species, such as hydrated iron-oxides, are commonly adsorbed.9 Vimonses et al.10 carried out the adsorption studies of congo red onto kaolin, sodium bentonite and zeolite. The equilibrium data of kaolin fitted the Langmuir model and the adsorption kinetic followed the pseudo-second order equation. Fumba et al.14 considered the efficiency of kaolinite, metakaolinite and activated geopolymer for the removal of methyl orange dye and reported that the adsorbed amount of methyl orange molecules increased with contact time and reached equilibrium in 15 min for kaolinite and then 10 min for metakaolinite. The optimum adsorption was observed at pH of 2.5, the equilibrium data fitted the Langmuir isotherm and for the kinetic model, a higher correlation value was observed for the pseudo-second order confirming that chemisorption was the rate-limiting step. Garg et al.15 investigated the removal of AB dye by zeolite. The optimal zeolite dose, adsorption time, and stirrer speed were reported to be 10 g/L, 6 h, and 300 rpm, respectively. Mouni et al.16 removed methylene blue dye by Algerian kaolin. The authors reported that the kinetic data fitted the pseudo-second order model. The equilibrium data was explained by the Langmuir isotherm, indicating that the maximum adsorption capacity equals 52.76 mg/g at 25°C and pH 6, moreso, the thermodynamic data demonstrated that the adsorption is spontaneous and increase with increasing temperature.

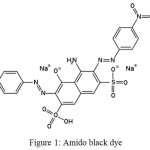

Amido black (AB) dye also known as disodium salt or naphthol blue black (Figure 1). It is a synthetic acid dye used in biochemical research to stain for total protein and criminal investigations to detect blood present with latent fingerprints. The IUPAC name is sodium 4-amino-5-hydroxy-3-((E)-(4-nitrophenyl)diazenyl)-6-((E)-phenyldiazenyl)naphthalene-2,7-disulfonate.

|

Figure 1: Amido black dye |

Although few studies have reported the adsorption of different dyes onto kaolin, detailed literature survey revealed no previous work on the adsorption studies of AB dye onto kaolin. Hence, the objective of this work was to determine the optimum process parameters involved in the kinetics, equilibrium and thermodynamic studies of the adsorption of AB onto kaolin in batch modes under different reaction conditions. Moreover, this study focused on the development of effective and efficient adsorption process using naturally occurring kaolin clay mineral as a cheap and environment friendly substitute to the commonly used activated carbon.

Materials and Methods

Chemicals and Reagents

AB dye were purchased from Merck (Germany) and was used without further treatment. Kaolin of about 2.0 kg was collected from New CBN road, Ado-Ekiti, Nigeria and air-dried at room temperature for 5 days. The kaolin was further placed in an oven set at 60oC for 3 h before being crushed and was sieved with a mesh (125 µm). The moisture content, ash content, pH and loss of mass on ignition of the kaolin are 4.5±0.004%, 0.937±0.02%, 8.2 and 0.005±0.002%, respectively.

Characterization of kaolin

The mineralogical, functional groups, crystallographic properties and morphology of the kaolin mineral ore were investigated prior to the adsorption studies by using the x-ray diffraction (Siemens D8 Advance Bruker XRD), attenuated total reflection – Fourier transform infrared spectroscopy (Perkin Elmer Spectrum TwoTM spectrometer), scanning electron microscopy (Nova Nano SEM 230), energy dispersive spectroscopy (EDS) and the transmission electron microscopy (Tecnai G2 20).

Adsorption Procedure

For the effect of kaolin dosage, a range of kaolin 0.25 g – 1.25 g was added to 20 mL of 40 mg/L of AB dye concentration and stirred with a magnetic stirrer at 200 rpm for 10 min. To study the influence of pH, 20 mL of 40 mg/L of AB solutions were adjusted with 0.01 M HCl and NaOH to a pH range 3-11, followed by the addition of 0.75 g of kaolin. The mixtures were stirred at ambient temperature for 20 min at 200rpm. For the effect of initial AB concentration, a 20mL of initial AB concentration 20-100 mg/L were used in conjunction with 0.75 g kaolin and then placed in a conical flask at a speed of 200 rpm for 20 min. For the contact time, a 0.75 g kaolin was agitated with 20 mL of 40 mg/L AB solution for 5-60 min at 200rpm, whereas, thermodynamic study involves the use of 0.75 g kaolin agitation with 20 mL of 40 mg/L of AB dye at different temperature ranging from 293 K to 318 K for 20 min at 200rpm.

For all the experiments, aliquot was withdrawn after the contact time has elapsed and the absorbance recorded at 618 nm in a UV-visible spectrophotometer. The percentage AB dye removal was calculated with Equation 1 and the amount of AB dye adsorbed (qe; mg of AB dye per g kaolin) was obtained using Equation 2.

where Co is the initial concentration of AB dye solution, Ce (mg/L) is the equilibrium concentration of AB dye, V (mL) is the volume of the solution and W (g) is the mass of kaolin.

Results and Discussion

Characterization

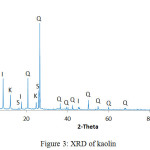

The morphological study of kaolin by SEM (Figure 2a) and TEM (Figure 2b) indicated the presence of booklets; the micron-sized morphological structures built up of numerous platelets that are typical for the kaolinite mineral17. The EDS (Figure 2c) as an attachment of the SEM showed that the kaolin constitutes C (24.31±4.38), O (53.44±1.71), Al (7.7±2.54) and Si (14.56±4.38). Figure 3 presents the diffractogram of kaolin. The peaks show the presence of quartz, kaolinite, illite and sillimanite.

|

Figure 2: SEM (a), TEM (b) and EDS spectrum (c) of kaolin |

|

Figure 3: XRD of kaolin |

Q – quartz (SiO2), K – kaolinite (Al2Si2O5(OH)4), I – illite (K,H3O)Al2Si3AlO10(OH)2), S – sillimanite (Al2SiO5)

FTIR studies as presented in Figure 4 showed that the kaolin exhibited bands at 3691.71 cm−1 and 3620.14 cm−1 which are characteristics of inner hydroxyls.18 Si-O bending vibration was observed at 1114.35 cm−1, 1029.07 cm−1 and 1004.45 cm−,1 19 while the stretching vibration was observed at 752.83 cm−1 and 690.20 cm−1. The band at 910.59 cm−1 corresponds to the Al-O bending vibration. The band at 531.47 cm−1 corresponds to the Si-O-Al stretching and the bands at 464.31 cm−1 and 423.13 cm−1 corresponds to the Si-O-Si bending.20

|

Figure 4: FTIR of kaolin |

Adsorption

The results of the effect of kaolin dosages on 40 mg/L AB dye is as presented in Figure 5. The figure showed that for AB concentration of 40 mg/L and for a contact time of 10 min, an increase of the mass of kaolin from 0.25 g to 0.75 g increases the percentage of AB dye removed in solution from 19.0% to 28.80%, after which equilibration was attained. The increase in the percentage of AB dye removed from solution might be as a result of the increase in the number of active sites of the kaolin as the dosage increases. The trend of the graph is similar to the result by Amrhar et al.21 who investigated the removal of methylene blue from aqueous solution by Moroccan illitic clay. A 0.75 g kaolin sample was kept constant for further studies.

|

Figure 5: Effect of kaolin dosage on AB dye adsorption |

The influence of pH mostly depends on the ions present in solution as well as on electrostatic interactions with the adsorbent surface. The pH of a solution affects the aqueous chemistry and surface binding sites of the adsorbents. Figure 6 shows the effect of pH on the adsorption capacity of kaolin. It was found that as the pH increased from 3 to 11, the adsorption capacity of kaolin increased from 0.16 mg/g (15.0%) to 0.35 mg/g (32.75%).

|

Figure 6: Effect of pH on AB dye adsorption |

|

Figure 7: Effect of initial dye concentration on AB adsorption |

The initial concentration gives details on whether the adsorption of contaminants on the adsorbent surface occurs through the formation of monolayer or multi-layers. Monolayer adsorption could be explained by the Langmuir isotherm, whereas, multilayer adsorption is given by Freundlich isotherm. A plot of the percentage AB dye removed from solution versus the initial AB concentration is as shown in Figure 7. Although the qe increased from 0.17 mg/g – 0.59 mg/g as the initial AB concentration increases from 20-100 mg/L (Figure 7b), the percentage of AB removed decreased from 32.1% to 22.1% (Figure 7a). There was a decrease in the percentage of AB dye removal since the adsorption was carried out against fixed number of active sites, these active sites became saturated at higher AB concentration.

The linearized form of the Langmuir22 and Freundlich23 models are presented in Equations 3 and 4, respectively.

Where Ce, qe, qm and n are the equilibrium concentration of AB dye solution (mg/L), amount of AB dye adsorbed per unit mass of kaolin (mg/g), Langmuir constant representing adsorption capacity (mg/g) and the number of layers, respectively. KL and KF are the Langmuir constant representative of the energy of adsorption (L/mg) and the Freundlich constant (mg/g (L/mg)1/n), respectively.

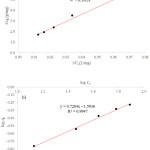

The equilibrium adsorption plots have high regression coefficient value of 0.9919 for Langmuir and 0.9947 for Freundlich, this shows that AB dye adsorption onto kaolin suit both the Langmuir and Freundich equilibrium models. The equilibrium constants obtained were presented in Table 1. The Freundlich constant n within the range 1–10 indicates good adsorption.

|

Figure 8: Langmuir (a) and Freundlich (b) isotherms of AB dye adsorption onto kaolin |

Table 1: Equilibrium and kinetic constants for AB adsorption onto kaolin

|

Equilibrium models |

|||||

|

Langmuir |

Freundlich |

||||

| (mg/g) | (L/mg) | R2 | (mg/g (L/mg)1/n) | n | |

| 1.1418 | 0.0128 | 0.9919 | 0.0255 | 1.3729 | 0.9947 |

|

Kinetic models |

|||||

|

Pseudo-first order |

Pseudo-second order |

||||

| 0.0159 | 0.7885 | 0.9153 | 0.0699 | 0.8519 | 0.9847 |

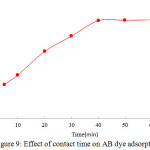

The results obtained on the effect of contact time is used to determine the efficiency of the adsorption process, equilibrium time and the kinetics. AB adsorption was found to increase rapidly from 5-40 min, however, equilibrium was attained afterwards from 40 and 60 min (Figure 9). The percentage AB removal increased from 20.98 to 60.75%, corresponding to 0.21 to 0.61 mg/g, respectively. The increase might be attributed to a higher surface area of kaolin being made accessible with time for the adsorption of AB dye molecules.

|

Figure 9: Effect of contact time on AB dye adsorption |

Equations 5 and 6 presents the pseudo-first and pseudo-second order kinetic models, respectively.

where qe and qt are the equilibrium amount of AB adsorbed per unit mass of kaolin (mg/g), and the amount of AB adsorbed per unit mass of kaolin at time t (mg/g), respectively. k1 is the pseudo-first order adsorption rate constant, k2 is the pseudo-second order rate constant, and t is time (min).

The modelled pseudo-first and pseudo-second order kinetics of the adsorption of AB dye onto kaolin are presented in the Figures 10a and 10b, respectively. The kinetic plots showed that the adsorption followed the pseudo-second order equation having a higher regression coefficient value of 0.9847. Table 1 also presents the calculated kinetic parameters and regression coefficient values.

|

Figure 10: Pseudo-first (a) and pseudo-second (b) order kinetic models |

Figure 11 indicated that the adsorption capacity of kaolin onto AB increased with increasing temperature, increasing from 22.93% at 293 K to 30.75% at 308 K. This implies that the mobility of AB molecules increased with temperature. In addition, the increase of the temperature of the solution might reduce the viscosity of the dye, thereby increasing the rate of diffusion of AB molecules across the external boundary layer and in the internal pores of the kaolin particles.24 The amount of AB dye adsorbed was constant afterwards (308-318 K).

|

Figure 11: Effect of temperature (a) and the Van’t Hoff plot (b) Click here to View figure |

The standard enthalpy (ΔHo), entropy (ΔSo) and free energy (ΔGo) changes were obtained from thermodynamic equations presented in Equations 7-9.

where Co-Ce is the amount of the AB dye adsorbed per litre, Ce is the equilibrium concentration of solution (mg/L), T is temperature in Kelvin, R is the ideal gas constant (8.314 J /mol/K) andKis the thermodynamic equilibrium constant. A plot of log K agains

![]()

gave ΔH° and ΔS° from the slope and intercept of Equation 9, respectively.

Table 3: Thermodynamic parameters

| T (K) | ΔHo kJ/mol | ΔSo J/mol/K | ΔGo kJ/mol |

| 293 | 11.949 | 31.445 | 2.953 |

| 298 | 2.483 | ||

| 303 | 2.280 | ||

| 308 | 2.079 | ||

| 313 | 2.112 | ||

| 318 | 2.146 |

The Van’t Hoff plot is as shown in Figure 11b. The obtained ΔHo, ΔSo and ΔGo for the adsorption of AB onto kaolin are presented in Table 2. The value ΔHo is positive (11.949 kJ/mol), which implies that the adsorption process is endothermic. ΔGo is also positive, an indication that the adsorption process is non-spontaneous. This is supported by Amin et al.,25 the authors reported that the adsorption of malachite green dye by Acacia nilotica waste is endothermic and nonspontaneous at all temperatures.

Conclusion

The application of kaolin as a cheap and natural adsorbent for the remediation of AB dye was investigated. Experimental results indicated that the adsorption of AB onto kaolin increased with increasing kaolin dosage, contact time, pH and temperature, nevertheless, adsorption decreased with increase in initial AB concentrations. The equilibrium data obeyed the Langmuir and Freundlich adsorption models, the kinetic data followed the pseudo-second order equation, whereas, the thermodynamic parameters indicated that the adsorption process is endothermic and non-spontaneous at the concentration of AB dye and temperatures considered. The mineral phases of the kaolin used in this study are quartz, kaolinite, illite and sillimanite, therefore, the effectiveness of kaolin for the removal of AB dye might be ascribed to the surface properties and mineralogical composition of kaolin.

References

- WHO/UNICEF, Global Water Supply and Sanitation Assessment Report 2000, WHO, Geneva, 2000.

CrossRef - Gupta V.K., J. Environ. Manage. 2009, 90(8), 213-2342.

CrossRef - Yagub, M.T., Sen, T.K., Afroze, S. and Ang, H.M., Adv. Colloid Interface Sci. 2014, 209, 172-184.

CrossRef - Ayanda, O.S., Odo, E.A., Malomo, D., Sodeinde, K.O., Lawal, O.S., Ebenezer, O.T., Nelana, S.M. and Naidoo, E.B., Clean – Soil, Air, Water 2017, 45(12), doi: 10.1002/clen.201700537

CrossRef - Kant R., J. Water Resour. Prot. 2012, 4(2), 93-98.

CrossRef - Meshko V., Markovska, I., Minchev, M., and Rodrigues, A.E., Water Res. 2001, 35(14), 3357-3366.

CrossRef - Bhatnagar, A., and Sillanpaa, M., Chem. Eng. J. 2010, 157, 277-296.

CrossRef - Lee, S.O., Tran, T., Jung, B.H., Kim S.J., and Kim, M.J., Hydrometallurgy 2007, 87(3-4), 91-99.

CrossRef - Veglio, F., Passariello, B., Esposito, M.A., and Marabini, A.M., In: Atak, O., Onal, I., Celik, I. (Eds.), Innovation in Mineral and Coal Processing, Balkema, Rotterdam, 1998, 37, 265–270.

- Vimonses, V., Lei, S., and Jina, B., Chem. Eng. J. 2009, 148(2), 354–64.

CrossRef - Besraa, L., Senguptaa, D., Royb, S., and Ay P., Int. J. Miner. Process. 2002, 66(1-4), 203-232.

CrossRef - John, C.W., Mineral commodity summaries, the mineral industry of Malaysia. U.S. Geological Survey Minerals Yearbook 2002, 8, 16.1-16.8.

- Grimshaw, R.W., Physics and Chemistry of clay, 4th edition, 1971, Ernest Benn, London.

- Fumba, G., Essomba, J.S., Tagne, G.M., Nsami, J.N., Bélibi, P.D., and Mbadcam, J.K., J. Acad. Ind. Res. 2014, 3(4), 156-163.

- Garg, A., Mainrai, M., Bulasara, V.K., and Barman, S., Chem. Eng. Comm. 2015, 202(1), 123-130.

CrossRef - Mouni, L., Belkhiri, L., Bollinger, J.C., Bouzaza, A., Assadi, A., Tirri, A., Dahmoune, F., Madani, K., and Remini, H., Appl. Clay Sci. 2018, 153, 38-45.

CrossRef - Ivanić, M., Vdović, N., Barreto, S.D., Bermanec, V., and Sondi, I., Geologia Croatica 2015, 68(2), 139-145.

CrossRef - Dawodu, F.A., and Akpomie, K.G., J. Mater. Res. Technol. 2014, 3(2):129-141.

CrossRef - Mgbemena, C.O., Ibekwe, N.O., Sukumar, R., and Ravindranatha, M.A.R.. Journal of King Saud University–Science 2013, 25, 149-155.

CrossRef - Saikia, B.J., and Parthasarathy, G., J. Mod. Phys. 2010, 1,206-210.

CrossRef - Amrhar, O., Nassali, H., and Elyoubi, M.S., J. Mater. Environ. Sci. 2015, 6(11), 3054-3065.

- Freundlich, H., J. Phys. Chem. 1907, 57, 385-470.

- Langmuir, I., J A Chem. Soc. 1918, 1361-1403.

CrossRef - Elass, K., Laachach, A., Alaoui, A., Azzi, M., Appl. Clay Sci. 2011, 54(1):90-96.

CrossRef - Amin, M.T., Alazba, A.A., and Shafiq, M., Water Sci. Tech. 2017, 76(7):1805-1815.

CrossRef

This work is licensed under a Creative Commons Attribution 4.0 International License.