Areca Fiber Reinforced Epoxy Composites: Effect of Chemical Treatments on Impact Strength

S. Dhanalakshmi1,2, P. Ramadevi1,2 and B. Basavaraju3*

1Department of Chemistry, Jawaharlal Nehru Technological University, Hyderabad - 500085, India 2Department of Chemistry, KLE Society’s BVB College of Engineering & Technology, Hubballi-580031, India. 3Department of Chemistry, Alva’s Institute of Engineering and Technology, Mijar-574225, India.

DOI : http://dx.doi.org/10.13005/ojc/310218

Article Received on :

Article Accepted on :

Article Published : 08 Jun 2015

In this research work, impact strength of untreated, alkali treated, potassium permanganate treated, benzoyl chloride treated and acrylic acid treated areca fiber reinforced epoxy composites were studied under 40%, 50%, 60% and 70% fiber loadings. Impact strength increased with increase in fiber loading up to 60% and then showed a decline for all untreated and chemically treated areca fiber reinforced epoxy composites. The acrylic acid treated areca fiber reinforced epoxy composites with 60% fiber loading showed highest impact strength of 28.28 J/mm2 amongst all untreated and chemically treated areca/epoxy composites with same 60% fiber loading.

KEYWORDS:Areca fibers; chemical treatments; epoxy resin; polymer composites; impact strength.

Download this article as:| Copy the following to cite this article: Dhanalakshmi S, Basavaraju B, Ramadevi P. Areca Fiber Reinforced Epoxy Composites: Effect of Chemical Treatments on Impact Strength. Orient J Chem 2015;31(2). |

| Copy the following to cite this URL: Dhanalakshmi S, Basavaraju B, Ramadevi P. Areca Fiber Reinforced Epoxy Composites: Effect of Chemical Treatments on Impact Strength. Available from: http://www.orientjchem.org/?p=9140 |

Introduction

At present natural fibers are gaining tremendous importance to be used as a reinforcement material for the preparation of polymer composites as these natural fibers are having excellent benefits such as good strength and stiffness, low cost, eco-friendly nature, renewable and degradable properties.

The natural areca fiber is inexpensive, abundantly available and a very high potential perennial crop. The botanical name of areca is Areca Catechu Linnaeus and it belongs to the Arecaceae (Palmae), palm family and Arecoideae subfamily. Karnataka is India’s largest areca nut producing state which has a share of around 50% areca productions in the country. In Dakshina Kannada, areca is one of the major crops and is cultivated in 27,600 hectares with an annual production of about 40,000 tonnes. Hence, enormous quantity of unmanaged areca husk is available for further processing. The areca husk is a hard fibrous material covering the endosperm and constitutes about 60-80% of the total weight and volume of the areca fruit. The areca husk fiber is composed of cellulose with varying proportions of hemicelluloses (35–64.8%) and lignin (13.0–26.0%), pectin and protopectin1-3. Presently, this highly cellulosic material is being used as a fuel in areca nut process. Thus the use of this husk fiber as structural material requires a detailed study on physical, chemical and mechanical characteristics.

Mechanical behaviour of areca composites was studied by few investigators and they found to have a good flexural strength and adhesion tensile properties at 60% fiber loading4-8. Alkali treated areca/epoxy and alkali treated areca/polypropylene composites showed improved tensile strength values 9-10. Chemical interlocking at the interface was enhanced and better adhesion with the matrix was observed after potassium permanganate treatment of natural lignocellulosic fibers10-11. 6% and 33% improvement on tensile strength and moisture resistance properties were reported for benzoyl chloride treated flax fiber reinforced low density polyethylene composites12. Acrylic acid treated abaca fiber reinforced polypropylene composites showed better mechanical performance compared to untreated abaca/polypropylene composites13. Acrylated jute fiber reinforced epoxy-phenolic matrix composites showed increase in tensile strength and flexural strength values by 42.2% and 13.9% respectively14. Flexural strength and impact strength increased with increase in fiber loading up to 50% for abaca reinforced MAH-PP composites15. Abaca-epoxy polymer composites showed increase in impact strength up to 40% fiber loading and then showed a decline. Benzene diazonium chloride treated abaca-epoxy composites with 40% fiber loading showed high impact strength value compared to untreated and other chemically treated abaca-epoxy composites with same 40% fiber loading16. Several researchers showed that impact strength increased with increase in fiber loading17-19.

Hence, surface modifications of natural fibers by chemical treatments are more important in the field of technical utilization of natural fiber reinforced polymer composites in various engineering applications. Epoxy resin is the most commonly used matrix material in natural fiber reinforced polymer composite fabrication because of its good adhesive nature, good chemical and environmental resistance, good electrical insulating properties and good mechanical properties.

Impact strength is the capability of the material to withstand a suddenly applied load and impact tests are used in studying the toughness of a material. Impact strength is a very important property of a material governing the life of a structure. The capacity of the aircraft to withstand the impact depends on the strength of the material.

In the present study, areca fibers were treated with alkali, potassium permanganate, benzoyl chloride and acrylic acid to improve interfacial adhesion between the fiber and epoxy resin and to fabricate areca fiber reinforced epoxy composites with improved mechanical properties. Untreated and all chemically treated areca fiber reinforced epoxy composites were prepared with 40%, 50%, 60% and 70% fiber loadings. The impact strength of all untreated and chemically treated areca fiber reinforced epoxy composites were evaluated by following standard procedures. The aim of this research work is to study the effect of chemical modifications on impact strength of areca fiber reinforced epoxy composites under different fiber loadings.

Materials and Methods

Materials

Areca empty fruits were obtained from Madhu Farm House, Nilogal, Davangere, Karnataka, India. The analytical grade reagents were purchased from Qualigens Company and used as received.

Fiber Extraction

The dried areca empty fruits were soaked in de-ionized water for about five days. This process is called retting; allowing the fiber to be removed from the fruit easily. The fibers were removed from the fruit and separated with a comb. After drying in the room temperature, the fibers were combed in a carding frame to further separate the fibers into an individual state. Then a sieve was used to remove broken fibers and impurities. The resulting fibers were treated in the condition (temperature 30 oC, RH 70%) for 72 h before the chemical treatment.

Alkali treatment

Areca fibers were soaked in a stainless steel vessel containing 6% NaOH solution at the room temperature (30-32 oC) for 1h. The alkali treated fibers were immersed in distilled water for 24 h to remove the residual NaOH. Final washing was done with distilled water containing little amount of acetic acid. Fibers were dehydrated in an oven at 70 oC for 3 h.

Potassium permanganate treatment

Areca fibers, pre-treated with 6% alkali were immersed in 0.5% KMnO4 in acetone solution for 30 min. The fibers were then decanted and dried in air.

Benzoyl chloride treatment

During benzoylation treatment, 6% alkali pre-treatment was used to activate the hydroxyl groups of the fibers. This alkali pre-treated areca fibers were soaked in 6% NaOH and agitated with benzoyl chloride for 15 min. Then the treated areca fibers were soaked in ethanol solution for 1 h to remove benzoyl chloride that adhered to the fiber surface washed thoroughly using distilled water and dried in air.

Acrylic acid treatment

6% alkali treated areca fibers were immersed in 5% acrylic acid solution at 50 oC for a period of 1 h and then treated fibers were washed thoroughly using distilled water and dried in air.

Composite fabrication

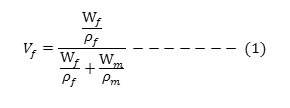

The composite preparation process was performed in the following order. First, the Epoxy-556 resin of density 1.15 – 1.20 g/cm3 and the HY951 hardener were mixed in 10:1 ratio. One half of resin was placed inside the mixing chamber for about 1 min at 20 RPM; then fibers were added over a period of 2 min. Then, the other half of the epoxy resin was placed inside the mixing chamber and the mixing speed was increased to 30 RPM for 5 min. The resulting material was compression molded at a pressure of 0.5 MPa using a Santec compression molding press. Finally, the composites were post-cured at room temperature for 15 days. The volume fractions 40%, 50%, 60% and 70% of fiber was carefully controlled during the mixing of two ingredients. The moulds have been prepared with dimensions of 300 mm × 300 mm × 10 mm. The equation (1) was used in the composite fabrication where Wf is the weight of fiber (g), Wm is the weight of matrix (g), Vf is the fiber volume fraction (%), ρm is the density of matrix (g/cm3) and ρf is the density of fiber (g/cm3).

Impact Strength

Specimens prepared for the impact strength test were cut with help of zig saw and impact energy absorbed by the specimens was determined by performing Charpy method of impact testing methods as per ASTM-D256-90 with notched specimens using Instron Pendulum Tester (9050 Manual Model). The width and depth of each specimen was measured with a micrometer screw gauge to the nearest 0.01 mm, and the length was measured to the nearest 0.1 mm with digital calliper. The mean specimen dimensions were used to calculate strength. For the test, specimen of length of 55 mm with square cross section of 10 mm side and the U notch is made at the center of the specimen for a depth of 5 mm. At least five replicate specimens were tested and the results were presented as an average of tested specimens. The impact tests were conducted at a standard laboratory atmosphere, 30±2 oC and 65% relative humidity (RH 65%).

Results and Discussion

Chemical treatments of areca fibers

Chemical treatments of natural fiber would remove the impurities like pectin, fat and lignin present in the fiber. After the chemical treatment a rougher fiber surface may result due to the introduction of some reactive groups into the fiber. Hence, chemical treatments facilitate efficient coupling with polymeric resin, improve interfacial properties and as a result natural fiber reinforced polymer composites with better mechanical properties can be obtained 3, 20-28.

Alkali treatment of areca fibers

Scheme 1. Reaction between areca fibers and sodium hydroxide

Fiber – OH + NaOH → Fiber – O– Na+ + H2O

Fiber–cell–O–Na groups are formed between the cellulose molecular chains due to the reaction of areca fiber with sodium hydroxide. There is a removal of hydrogen bonding in the network structure and formation of new reactive hydrogen bonds between the cellular molecular chains. As a result, the natural crystalline structure of the cellulose relaxed.

Potassium permanganate treatment of areca fibers

|

Scheme2: Reaction between areca fibers and potassium permanganate |

Highly reactive permanganate ions (Mn3+) react with cellulose hydroxyl groups and forms cellulose manganate. And also, areca fiber surface was carved due to the reaction of permanganate ions with the lignin constituents.

Benzoyl chloride treatment of areca fibers

|

Scheme3: Reaction between areca fibers and benzoyl chloride |

An ester linkage is formed by the reaction between benzoyl chloride and alkali treated areca fibers. This reduced its hydrophilicity and made it more compatible with polymer matrix. Benzoylation treatment also enhances thermal stability of areca fibers.

Acrylic acid treatment of areca fibers

|

Scheme4: Reaction between areca fibers and acrylic acid |

Acrylic acid provides more access of reactive cellulose macro radicals to the polymerization medium by reacting with the cellulosic hydroxyl groups of the fiber. During reaction with areca fiber, an ester linkage is formed by the carboxylic acids present in acrylic acid.

Impact strength

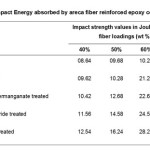

Impact strength is the capability of the material to withstand a suddenly applied load and is expressed in terms of energy per square cross section (J/mm2). Charpy impact test determines the amount of energy absorbed in Joules by a material during fracture and it is a measure of materials toughness. A material’s toughness is its ability to absorb energy during plastic deformation. It acts as a tool to study brittle – ductile transition. Brittle materials have low toughness and they can endure a small amount of plastic deformation. On impact, the energy of the pendulum is transferred to the test specimen and a part of the energy is consumed during fracture of the specimen. The impact strength of natural fiber reinforced polymer composites depends upon fiber aspect ratio and fiber rigidity. The total energy absorbed by the polymer composite is the sum of the energy consumed during plastic deformation and the energy needed for creating new surfaces. In this study, untreated and chemically treated areca/epoxy composites were fabricated with different fiber loadings of 40%, 50%, 60% and 70% and impact energy absorbed for all areca fiber reinforced epoxy composites are given in Table 1.

|

Table 1 Click here to View table |

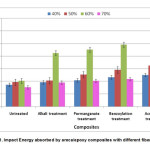

The impact energy absorbed for all untreated and chemically treated areca fiber reinforced epoxy composites with 40%, 50%, 60% and 70% fiber loadings are illustrated in Figure 1.

|

Figure1: Impact Energy absorbed by areca fiber reinforced epoxy composites with different loadings Click here to View figure |

It is very important to know optimum fiber loading to get good impact properties29. From Table 1 and Figure 1 it is observed that areca/epoxy composites with 60% fiber loading showed maximum impact strength values compared to areca/epoxy composites with other fiber loadings. Irrespective of the chemical treatment, all chemically treated areca/epoxy composites showed higher impact strength values than the untreated areca/epoxy composites.

In case of untreated areca/epoxy composites, the impact strength of 60% fiber loading increased by 18.52% compared to 40% fiber loading, 5.79% compared to 50% fiber loading and for 70% fiber loading it decreased by 25.39% compared to 60% fiber loading.

Alkali treatment of areca fibers resulted in reduced fiber diameter and thereby increased the aspect ratio. As a result effective fiber surface area for good adhesion with the matrix is increased 3, 23-26. Hence, alkali treated areca/epoxy composites showed increased impact strength values when compared with that of untreated areca/epoxy composites. In case of alkali treated areca/epoxy composites the impact strength of 60% fiber loading increased by 120.58% compared to 40% fiber loading, 106.42% compared to 50% fiber loading and for 70% fiber loading it decreased by 55.04% compared to 60% fiber loading.

Permanganate ions react with the lignin constituents and carve the fiber surface. And as a result areca fiber surface became rough. This improved chemical interlocking at the interface and provided better adhesion with the polymeric resin3,9,11. Because of this, permanganate treated areca/epoxy composites showed increased impact strength values when compared with that of untreated areca/epoxy composites. In case of potassium permanganate treated areca/epoxy composites, the impact strength of 60% fiber loading increased by 117.27% compared to 40% fiber loading, 78.55% compared to 50% fiber loading and for 70% fiber loading it decreased by 54.77% compared to 60% fiber loading.

Benzoylation treatment results in an introduction of ester linkage with areca fibers and it improved chemical interlocking at the interface and provided effective fiber surface area for good adhesion with the matrix3, 12, 23, 26-27. As a result, benzoylated areca fiber reinforced epoxy composites showed increased impact strength values when compared with that of untreated areca/epoxy composites. In case of benzoyl chloride treated areca/epoxy composites the impact strength of 60% fiber loading increased by 112.46% compared to 40% fiber loading, 68.45% compared to 50% fiber loading and for 70% fiber loading it decreased by 55.78% compared to 60% fiber loading.

Acrylic acid replaced hydrophilic hydroxyl group by hydrophobic ester groups in the areca fiber and it increased effective fiber surface area for good adhesion with the matrix and enhanced stress transfer capacity at the interface and improved the impact strength3, 13, 22. As a result, for acrylic acid treated areca/epoxy composites, higher impact strength values are observed when compared with that of untreated areca/epoxy composites. In case of acrylic acid treated areca/epoxy composites the impact strength of 60% fiber loading increased by 125.52% compared to 40% fiber loading, 74.14% compared to 50% fiber loading and for 70% fiber loading it decreased by 59.12% compared to 60% fiber loading.

With increase in fiber loading from 40% to 60%, the impact strength values of all untreated as well as chemically treated areca/epoxy composites increased and beyond 60% fiber loading impact strength showed a decline. That means maximum impact strength was given by areca/epoxy composites with 60% fiber loading. This is because of better fiber distribution in matrix, less fiber fractures and effective transfer of load from matrix to fibers at 60% fiber loading. As fiber loading increases, more force is required to pullout the fibers thereby increasing the impact strength. The observed increase in impact strength values with chemical modification and as well as with increase in fiber loading up to 60% is in good agreement with the results reported in literature 15-19.

One of the reasons for decrease in impact strength after 60% fiber loading in all untreated and chemically treated areca/epoxy composites is due to fiber pullout. The decrease in impact strength may be due to the micro spaces between the fiber and the matrix which initiates micro cracks on impact and results in crack propagation leading to failure 19.

Alkali treated, potassium permanganate treated, benzoyl chloride treated and acrylic acid treated areca/epoxy composites with 60% fiber loading showed 107.23%, 121.09%, 139.84% and 176.17% increase in impact strength values respectively when compared to untreated areca/epoxy composites with same 60% fiber loading. Amongst all the chemical treatments carried out, acrylic acid treated areca fiber reinforced epoxy composites of 60% fiber loading showed maximum impact strength values. These results clearly evidenced that chemical treatments are very effective in surface modification of the areca fiber and in improving the mechanical properties of chemically treated areca/epoxy composites.

Conclusions

The investigation showed that the impact strength of all untreated and chemically treated areca fiber reinforced epoxy composites increased with increase in fiber loading up to 60% and beyond it showed a decline. Maximum value of impact strength is observed at 60% fiber loading for all untreated and chemically treated areca/epoxy composites. Impact strength value of untreated areca/epoxy composites with 60% fiber loading is 10.24 J/mm2. Amongst all the chemical treatments carried out, acrylic acid treated areca/epoxy composites of 60% fiber loading showed maximum impact strength value of 28.28 J/mm2, followed by benzoyl chloride treatment, potassium permanganate treatment and alkali treatment with impact strength values of 24.56 J/mm2, 22.64 J/mm2 and 21.22 J/mm2 respectively at 60% fiber loading. So, these chemically treated areca fiber reinforced epoxy composites with 60% fiber loadings are best suitable for applications where high impact strength is required.

Acknowledgements

This work was supported by Vision Group on Science and Technology, Department of Information Technology, Biotechnology and Science & Technology, Government of Karnataka, India (grant number VGST/CISEE/2012-13/282 dated March 16, 2013). The first author would like to thank the Management of K.L.E. Society’s B.V.B. College of Engineering and Technology, Hubballi, Karnataka, India for the kind encouragement and constant support provided. She sincerely thanks Dr. Ashok S. Shettar, Principal, K.L.E. Society’s B.V.B. College of Engineering and Technology, Hubballi, for his encouragement and support throughout this work.

References

- Rajan, A.; Kurup, J. G.; Abraham, T. E.; Biochem. Eng. J. 2005, 25(3), 237-242

- Dhanalakshmi, S.; Ramadevi, P.; Srinivasa, C. V.; Basavaraju, B.; Int. J. Agr. Sci. 2012, 4(4), 227-229

- Dhanalakshmi, S.; Ramadevi, P.; Basavaraju, B.; Raghu, P. R.; Srinivasa, C. V.; Journal of Advances in Chemistry. 2014, 10(10), 3263-3273

- Srinivasa, C. V.; Basavaraju, B.; Mownesh, G. K.; Raghu, P. G. R.; BioResources. 2010, 5(3), 1845-1858

- Srinivasa, C. V.; Arifulla, A.; Goutham, N.; Santoshkumar.; Mater. Design. 2011, 32(4), 2469-2475

- Srinivasa, C. V.; Bharath, K. N.; Journal of Material and Environmental Science. 2011, 2(4), 351-356

- Srinivasa, C. V.; Suresh, Y. J.; Premakumar, W. P.; Adv. Polym. Tech. 2011, 31(4), 319-330

- Swamy, R. P.; Mohankumar, G. C.; Vrushabhendrappa, Y.; J. Reinf. Plast. Comp. 2004, 23(13), 1373-1382

- Dhanalakshmi, S.; Ramadevi, P.; Raghu, P. G. R.; Manikanta, M.; Kiran, K.; Jayaraj, A.; Jason, M.; Chethan, G. R.; Basavaraju, B.; Ciencia-e-Tecnica. Vitivinicola. 2014, 29(8), 99-114

- Dhanalakshmi, S.; Basavaraju, B.; Ramadevi, P.; International Journal of Material Sciences and Manufacturing Engineering. 2014, 41, 1151–1156

- Sherely, A. P.; Boudenne, A.; Ibos, L.; Composites: Part A. 2008, 39, 1582-1588

- Wang, B.; Panigrahi, S.; Tabil, L.; Crerar, W.; J. Reinf. Plast. Compos. 2007, 26(5), 447–463

- Ramadevi, P.; Dhanalakshmi, S.; Basavaraju, B.; Pramod, V. B.; Journal of Advances in Chemistry. 2014, 10(6), 2803-2811

- Patel, V. A.; Parsania, P. H.; J. Reinf. Plast. Compos. 2010, 29(5), 725–30

- Girones, J.; Lopez, J. G.; Vilaseca, F.; Bayer, J.; Herrera-Franco, R. P. J.; Mutje, P.; Compos. Sci. Technol. 2011, 71(2), 122-128

- Ramadevi, P.; Dhanalakshmi, S.; Basavaraju, B.; Raghu, P.; Srinivasa, C. V.; International Journal of Sciences: Basic and Applied Research. 2014, 18(2), 305-317

- Md. Rezaur, R.; Mahbub, H.; Md. Monimul, H.; Md. Nazrul, I.; J. Reinf. Plast. Compos. 2010, 29(3), 445-455

- Jayaraman, K.; Compos. Sci. Technol. 2003, 63, 367-374

- Srinivasa, C. V.; Bharath, K. N.; International Journal of Chemical, Nuclear, Metallurgical and Materials Engineering. 2013, 7(4), 133-137

- Maya, J. J.; Anandjiwala, R. D.; Polym. Compos. 2008, 29(2), 187-207

- Kabir, M. M.; Wang, H.; Aravinthan, T.; Cardona, F.; Lau, K. T.; Composites Part B. 2012, 43(2), 159-169

- Kabir, M. M.; Wang, H.; Lau, K. T.; Composites Part B. 2012, 43, 2883-2892

- Xue, L.; Lope, G. T.; Satyanarayan, P.; Polym. Environ. 2007, 15(1), 25-33

- Leonard, Y. M.; Nick, T.; Andrew, J. C.; Macromol. Mater. Eng. 2007, 292(9), 993-1000

- Dipa, R.; Sarkar, B. K.; Rana, A. K.; Bose, N. R.; Bull. Mater. Sci. 2001, 24(2), 129-135

- Joseph, P. V.; Studies on short Sisal fibre reinforced Isotactic Polypropylene Composites. PhD Thesis. Mahatma Gandhi University, India, 2001.

- Manikandan, N. K. C.; Thomas, S.; Groeninckx, G.; Compos. Sci. Technol. 2001, 61(16), 2519-2529

- Joseph, K.; Thomas, S.; Pavithran, C.; Polymer. 1996, 37(23), 5139-5149

- Bledzki, A. K.; Mamun, A. A.; Faruk, O.; eXPRESS Polymer letters. 2007, 1(11), 755-762

This work is licensed under a Creative Commons Attribution 4.0 International License.