Chemical characteristics of gel obtained from blend of colostrum and skim milk under different heat treatments conditions

Manikant Kumar*1, Kavita Banjare2 and Sudhir Uprit1

1Department of Dairy Technology, College of Dairy Technology, CGKV, Raipur-492001, India. 2Central Research Laboratory, IGKV, Raipur, India.

DOI : http://dx.doi.org/10.13005/ojc/300454

Article Received on :

Article Accepted on :

Article Published : 15 Dec 2014

Study was carried out to evaluate the chemical characteristics of colostrums and skim milk blended heat treated product. The present study was confined to standardization of colostrum harvested from 2nd milking of gir breed of cow based product in combination with skim milk, sugar and cardamom powder. The blends proportions of skim milk were @ 15, 30, 45% and addition of 8% cane sugar was found to impart the desired sweetness. Green cardamom powder was used as flavouring agent. These mixtures were kept in a water bath at 3 different temperatures viz. 60, 70 and 75⁰C for 30 minutes. Gelation occurs on heating to yield curd like products of different gel strength, which were cooled at room temperature and analysed for different chemical attributes like fat, protein, acidity etc. The results indicated that the fat, protein, acidity content decreased significantly (p˂ 0.01) however the moisture, total carbohydrate increased significantly (p˂0.01) but ash differed non significantly with increased in skim milk proportion in blend at different temperatures.

KEYWORDS:Chemical attributes; Colostrum; Skim milk; Heat treatment

Download this article as:| Copy the following to cite this article: Kumar M, Banjare K, Uprit S. Chemical characteristics of gel obtained from blend of colostrum and skim milk under different heat treatments conditions. Orient J Chem 2014;30(4). |

| Copy the following to cite this URL: Kumar M, Banjare K, Uprit S. Chemical characteristics of gel obtained from blend of colostrum and skim milk under different heat treatments conditions. Available from: http://www.orientjchem.org/?p=5855 |

Introduction

Colostrum is the nutrient-rich, secretion produced by mammals within 24 to 72 hours after parturition. It is a mixture of lacteal secretions and constituents of blood serum, notable immunoglobulin and serum proteins that accumulate in mammary gland during the prepartum dry period can be harvested immediately after parturition (Foley and Otterby 1978). According to Elfstr and et al. (2002) colostrum is defined as pooled product collected in three time intervals from 0 to 50 hours postpartum. It contains various proteins, carbohydrates, fats, vitamins, and minerals that are essential for the diet of a developing mammalian neonate. It also includes bioactive constituents such as immunoglobulins, antimicrobial peptides and growth factors. Due to the presence of these important constituents colostrum can be used as functional foods. Approximately 5-10 litres of colostrum per milking is normally obtained from a dairy cow (Moore et al. 2005). An average production of colostrum is 43.5 kg per cow and an average consumption is 11 kg per calf during first three days post-partum gives 32.5 kg of surplus colostrum (Kulkarni and Pimpale, 1989). There are number of different colostrum based milk products manufactured by surplus colostrum. The excess colostrum can be processed for nutraceutical products (Moore et al. 2005) and purports numerous health benefits.

One basic property of colostrum is the ability to form gel on heating. Gelling occurred when colostrum are heated in a boiling water bath. Low-heat processed bovine colostrum products have a minor loss of bioactive substances. The concentration of bioactive substances decreases on different rate that depends on the severity of heat treatment. It is observed that reduction of Immunoglobulin at 65⁰C for 30 minute is 18.54% and at 68⁰C for 30 minute is 22.87% (Das and Seth 2011). The gel strength decreased greatly with increase in time of post-partum and increased with increase in temperatures began from 64⁰C for 1st milking and 76⁰C for 4th milking (Kulkarni and Pimpale, 1988). This gel property has been traditionally used to prepare sweet desserts. The gel obtained with first and second milking is very tough and therefore it is common practice to dilute the colosturm with milk or water to obtain gel of suitable textural attributes. The present study is a preliminary report on physico-chemical attributes of such gels formation of colostum harvested from second milking from gir cow, which were blended with skim milk. Bearing in mind the fact that colostrums and its components are very sensitive to heat and other conditions, its processing at low heat treatment can be preserve its bioactivity. Therefore present study was undertaken in order to make the standardize process parameters for preparation of colostrum based product blended with skim milk and analysed for effect of heat treatments on chemical characteristics of gel obtained from colostrum and skim milk blended (CSMB) product.

Materials and Methods

Collection of Materials

Colostrum was harvested from 2nd milking of cow from the farm located at Higna, Raipur managing only gir breed cow. The sample was immediately frozen to -20⁰C. Skim milk was obtained by separating the milk of cow from same heard (gir breed) and pasteurized in laboratory of College of Dairy Technology, Raipur, India. Cane sugar and green cardamom were procured from local grocer’s shop of Raipur, India.

Blend Proportion

Colostrum and skim milk were mixed in different proportion to obtain the different blend proportions. Sugar @ 8% and green cardamom powder @ 0.2% was also added. The detailed amount of each of the ingredient is given in Table 1.

Table 1: Quantities of each of the ingredients in blend

|

Blends |

Colostrum (%) | Skim milk (%) | Sugar (%) | Cardamom powder (%) |

|

B0 |

91.8 |

0 |

8 |

0.2 |

|

B1 |

76.8 |

15 |

8 |

0.2 |

|

B2 |

61.8 |

30 |

8 |

0.2 |

|

B3 |

46.8 |

45 |

8 |

0.2 |

Experimental Setup and Process flow

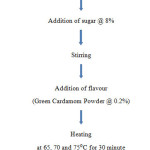

The blend as described in Table 1 was poured in rectangular size container (15cm×8cm) made up of aluminium. The container was filled with 200 ml blend which was 2/3rd of its capacity. Theses containers were kept in a water bath maintained at temperatures 65, 70 and 75°C for 30 minutes for obtaining the gel. The detailed flow diagram is given in Figure 1.

|

Figure1: Process Flow Line for blend Click here to View figure |

Chemical Analysis

Raw colostrum was analysed for specific gravity by using lactometer, fat and total solids by gravimetric method (SP: 18, part XI, 1981), Protein by Kel-plus nitrogen estimation system as described in A.O.A.C. (1995), ash and acidity determined by the method described in BIS (1989), pH values by using pH meter Hanna Instrument HI8417, Italy and total carbohydrate determined by the ‘By-difference’ method. Skim milk samples were analysed for fat by Gerber method and Solid-Not-Fat (SNF) by the Richmond’s formula. Chemical analysis of colostrum products blended with skim milk were analysed for moisture by method of (SP: 18, part XI, 1981), fat by using mojonnier apparatus described in IS: 2785 (1979), titratable acidity by the method recommended by the A.O.A.C (1984) for cheese, ash determined as per BIS (1989), Protein by the Kel-plus nitrogen estimation system as described in A.O.A.C. (1995) and the total carbohydrates including sucrose, dextrose, dextrin, maltose and lactose were calculated by the “By-difference” method [(subtracting sum of percentage of fat, protein and ash from total solids content(%)].

Statistical Analysis

Experiments were conducted using Unsymmetrical Factorial Randomized Block Design (Factorial RBD) of four treatments of three levels. The data obtained were analysed for physico-chemical attributes using statistical analysis software SPADE (Statistical Package for Analysis of Design of Experiments, version 3.0).

Results and Discussion

A chemical composition of harvested colostrum and skim milk is specified in Table 2. Analysis of variance of the data pertaining to various chemical attributes revealed that the gel obtained by different proportions of colostrum and skim milk blends cooked at different temperatures showed significant changes. Detailed findings and relevant discussion is given in following paragraphs.

Table 2: Chemical composition of colostrums and skim milk

|

Constituent |

Colostrum |

Skim milk |

| Fat |

6.21±0.05% |

0.4±0.1% |

| SNF |

– |

8.8±0.24% |

| Total Solids |

22.26±0.36% |

9.2±0.3% |

| Protein |

12.25±0.34% |

– |

| Titratable Acidity (%LA) |

0.347±0.011 |

0.12±0.06 |

| Ash |

0.953±0.04% |

– |

| pH |

6.28±0.12 |

– |

| Specific gravity |

1.044±0.001 |

– |

| Total carbohydrate |

2.85±0.08% |

– |

Moisture Content

The moisture content of colostrum based product blended with skim milk samples of different blend at different temperatures were differed significantly (P˂0.01) from each other and ranged from 60.35 (B0) to 68.63 (B3) per cent at 65 ºC, 58.705 (B0) to 67.175 (B3) per cent at 70 ºC and 56.589 (B0) to 66.81 (B3) per cent at 75 ºC presented in Figure 2(A).

|

Figure2: Effect of interaction (Blend x Temperature) of CSMB product on chemical attributes

|

These results are in accordance with the observations by Georgive, (2008) reported that the concentrations of many nutrients (proteins, vitamins, minerals etc.) and biologically active substances (immunoglobulin, enzymes, hormones, growth factors etc.) are many times higher in colostrum than in milk. The levels of skim milk incorporation influence (decreases) the concentration of colostrum of CSMB product samples as evident from the significant results for this parameter. Nangraj (2011), who resulted that increasing temperature caused some of the moisture to evaporate and thus resulted in decreasing the moisture content.

Fat Content

The fat content of colostrum based product blended with skim milk samples of different blend at different temperatures were differed significantly (P˂0.01) from each other and ranged from 10.56 (B0) to 4.225 (B3) per cent at 65 ºC, 11.50 (B0) to 5.45 (B3) per cent at 70 ºC and 12.20 (B0) to 6.25 (B3) per cent at 75 ºC respectively, presented in Figure 2(B).

The result showed that increase in temperature slightly increases the fat content of CSMB samples. These findings are in agreement to results by Nangraj (2011) and Abu Bakar et al. (2001), who reported that increase in temperature, resulted in slight increase in fat content.

Protein Content

The protein content of colostrum based product blended with skim milk samples of different blend at different temperatures were differed significantly (P˂0.01) from each other and ranged from 16.49 (B0) to 9.8 (B3) per cent at 65 ºC, 17.14 (B0) to 10.03 (B3) per cent at 70 ºC and 18.30 (B0) to 10.21 (B3) per cent at 75 ºC presented in Figure 2(C).

It was observed that the protein content increased with increased in temperature in heating process. These results are in favour of findings of Nangraj (2011), who also observed an increase in protein content of pasteurized milk due to loss of moisture and increase in total solids.

Ash Content

The ash content of colostrum based product blended with skim milk samples of different blend at different temperatures were differed non significantly (P˃0.05) from each other and ranged from 1.328 (B0) to 0.8773 (B3) per cent at 65 ºC, 1.356 (B0) to 0.668 (B3) per cent at 70 ºC and 1.3395 (B0) to 0.8612 (B3) per cent at 75 ºC respectively, presented in Figure 2(D).

The ash was changed dramatically as temperature was increased in the present study. The result supports the findings by Siddiqui et al. (2010), who found that there was no significant difference in milk samples heated at various temperatures.

Total Carbohydrate Content

The total carbohydrate content of colostrum based product blended with skim milk samples of different blend at different temperatures were differed significantly (P˂0.05) from each other and ranged from 11.26 (B0) to 16.46 (B3) per cent at 65 ºC, 11.29 (B0) to 16.47 (B3) per cent at 70 ºC and 11.56 (B0) to 16.52 (B3) per cent at 75 ºC presented in Figure 2(E).

The present findings showed that levels of skim milk incorporation increased total carbohydrate content of CSMB product samples due to higher value of lactose present in skim milk in respect of colostrum and increase in temperature resulted in increase the total carbohydrate level of CSMB samples. It could be observed that the total carbohydrate content of all the level of skim milk incorporation at three different temperatures differed significant for p<0.01 and p<0.05.

These findings agreed with the results of Nangraj (2011) and Hussain (2011), who stated that total carbohydrate content in milk samples pasteurized at various temperatures was slightly higher than that of control.

Acidity Content

The acidity content of colostrum based product blended with skim milk (CSMB) samples of different blend at different temperatures were differed significantly (P˂0.01) from each other and ranged from 0.4248 (B0) to 0.325 (B3) per cent of lactic acid at 65 ºC, 0.4475 (B0) to 0.3345 (B3) per cent of lactic acid at 70 ºC and 0.4738 (B0) to 0.3447 (B3) per cent of lactic acid at 75 ºC respectively, presented in Figure 2(F).

The result showed that increase in temperature slightly increases the acidity content of CSMB samples. These findings are in agreement to results by Walstra et al. (2006), Erdam and Yuksel (2005), who reported that increase in temperature, resulted in slight increase in acidity content of milk due to increase in concentration of lactic acid produced from degradation of lactose content during heating process.

Conclusion

Chemical attributes changes significantly with the composition, type and temperature of processing of CSBM products. There is significant effect of heat treatment on chemical properties of gel obtained from colostrums and skim milk blended products that revealed increased in percentage of fat, protein, total carbohydrate and acidity content where as decreased in moisture with increased in temperature but not significant resusult observed in ash content of CSMB product. The significant effect also observed by addition of skim milk on chemical properties of gel obtained from colostrums and skim milk blended products that give an idea about decreased in percentage of fat, protein, ash and acidity content where as increased in moisture and total carbohydrate content with increased in skim milk proportion in blend.

Acknowledgements

The authors are thankful to in charge of dairy farm located at Higna (Achoti), Kumhari, Ahirwara Road, Raipur, India, for providing colostrum during this investigation.

References

- A.O.A.C. Official Method of Analysis. 14th edn.; Washington, D.C., (1984)

- A.O.A.C. Official Method of Analysis. 16th edn.; Washington, D.C., (1995)

- Abubakar, T.; Sunarlim, R.; Setiyanto, H.; Nurjannah. Jurnal Ilmu Ternak dan Veteriner. 2001, 6,1, 45-50

- BIS. Hand Book of Food Analysis, Part XI; New Delhi, (1989)

- Das, A.; Seth, R. Ind. J. Dairy Sci. 2011, 64,5, 378-382

- Elfstrand, L.; Lindmark-Mansson, H.; Paulsson, M.; Nyberg, L.; Akesson, B. Int. Dairy J. 2002, 12, 879-887

- Erdam, Y. K.; Yuksel, Z. J. Dairy sci. 2005, 88, 1941-1946

- Foley, J. A.; Otterby, D. E. J. Dairy Sci. 1978, 61, 1033-1060

- Georgiev, P. Bulgarian J. Vet. Med. 2008, 11,1, 3-12

- Hussain, I. J. chem. Soc. Pak. 2011, 33,6, 781-784

- IS: 2785. Specification for natural cheese (Hard Variety), process cheese and process cheese spread and soft cheese . Bureau of Indian Standards, New Delhi, (1979)

- Kulkarni, P. R.; Pimpale, N. V. J. Dairy Res. 1988, 55, 117-120

- Kulkarni, P. R.; Pimpale, N. V. Ind. J. Dairy Sci. 1989, 42, 216-224

- Moore, M.; Tyler, J. W.; Munase, C.; Dawes, M.; Middleton, J. R. JAVMA. 2005, 226,8, 1375-1377

- Nangraj, N. K. Effect of pasteurization on physico-chemical characteristics and shelf life of buffalo milk. Thesis submitted to Sindh Agriculture University, Tandojam, Pakistan, (2011)

- Siddique, F.; Anjum, F. M.; Huma, N.; Jamil, A. Int. J. Agric. Biol., 2010, 12, 439-442

- SP: 18. Hand Book of Food Analysis, Part XI; Bureau of Indian standards, New Delhi, (1981)

- Walstra, P.; Wouters, J. T. M.; Geurts, T. J. Dairy Science and Technology, Taylor and Francis Group, LLC. New York, (2006)

This work is licensed under a Creative Commons Attribution 4.0 International License.