Electrorheological Behavior of Conducting Paste Containing Surfactant Capped Spherical Silver Nanoparticles

Prateek Shukla1, Tandra Nandi2 and Rajinder Pal Singh3

1Department of Chemistry, Indian Institute of Technology, Kanpur- 208016, India.

2Defence Materials and Stores Research and Development Establishment, G. T. Road, Kanpur-208013, India.

3B. L. Agro Oils Ltd., Bareilly-243502, India.

Corresponding Author E-mail: prateek.shukla8@gmail.com

DOI : http://dx.doi.org/10.13005/ojc/330429

Surfactant capped uniform silver nanoparticles were synthesized by the chemical reduction reaction in a microemulsion media, which is formed under high shear mixing condition. Silver nitrate solution and 2-ethyl hexanol were taken as aqueous and organic phase, sodium borohydride was used as reducing agent and Span-80 (sorbitanmonooleate) as the capping agent. Synthesized silver nanoparticles were characterized by transmission electron microscopy and dynamic light scattering technique for their size, shape and particle size distribution. The Crystalline structure of silver nanoparticles is ascertained by X- ray diffraction analysis. Uniform silver nanoparticles of average particles diameter (15-20) nm thus prepared have beenincorporated into fumed silica matrix using polyethylene glycol as the carrier fluid to prepare electrorheological (ER) paste. Different compositions of ER paste have been prepared using the different concentration of silver nanoparticles. The prepared electrorheological paste has shown commendable response with respect to viscosity and dynamic yield stress enhancement under applied electric field.

KEYWORDS:Silver nanoparticles;electrorheology; X-ray diffraction; transmission electron microscopy; dynamic light scattering and ER paste

Download this article as:| Copy the following to cite this article: Shukla P, Nandi T, Singh R. P. Electrorheological Behavior of Conducting Paste Containing Surfactant Capped Spherical Silver Nanoparticles. Orient J Chem 2017;33(4). |

| Copy the following to cite this URL: Shukla P, Nandi T, Singh R. P. Electrorheological Behavior of Conducting Paste Containing Surfactant Capped Spherical Silver Nanoparticles. Orient J Chem 2017;33(4). Available from: http://www.orientjchem.org/?p=34685 |

Introduction

In previous years, it had been a challenge for researchers to prepare metal nanoparticles with controllable size and shape. Silver nanoparticles have been the subject of many types of researches due to their high conductivity and stability. Nanoparticles exhibit highly improved properties like high conductivity, surface to volume ratio, energy, and enhanced optical properties1. Synthesis of nanoparticles via carrying out a chemical reaction in microemulsion medium had been one of the feasible and economical methods to get monodisperse nanoparticles in good yield2, 3.

Silver nanoparticles synthesis using a chemical reduction method mainly involves three main steps. First is the reduction aqueous silver salt by a reducing agent. Second is the mutual collision of newly formed silver atoms with each other to form of stable nuclei, this is called the growth of the nanoparticles it occurs until all metals ions present in the medium have been used up. The third and final step is the control of agglomeration of nanoparticles by a capping agent or surfactant. The capping agents with specific hydrophilic-lipophilic balance (HLB) provide surficial interaction with newly formed small nanoparticles during their growth stage to prevent agglomeration 4, 5,6, 7, 8, 9.Nanoemulsions formed by high energy methods involve the use of homogenizers which produce high mechanical force to break bigger macroscopic droplets into smaller nanodroplets. The main advantage associated with high energy methods is that capping agents or surfactants can be employed effectively to control agglomeration of various nanoparticles 10, 11, 12. However, fewer claimed their work suitable for bulk synthesis with controlled particle size distribution. A. Katiyar et al. have reported monodisperse Fe-Ni nanoparticles synthesis with regulated morphology for preparing magnetic nanofluid13.

Electrorheological (ER) paste normally consist of conducting particles (macro & micro-sized) suspended in a suitable carrier fluid with suitable additives. The previous researcher has shown the keen interest in particles like metal oxides, silica, aluminum silicates, various polymers, and organics, incorporated into suitable carrier fluids like aliphatic esters, fatty oils, silicone oils, sebacates, polyethylene glycols etc. Various types of additives have also been used to avoid the problem of sedimentation in ER fluids. These include cellulose, stearates, colloidal silica, polymethacrylate mixture, gypsum, dyes, poly-vinyl alcohol etc14.

Electrorheological (ER) fluids are suspensions consisting of dielectric particles of size ranging from 0.1 to 100 micrometers and a suitable carrier fluid. These ER fluids change some of its physical properties on the application of the electrical field, so they can be regarded as smart fluids. Electrorheological pastes have very high viscosities in order to retain conducting particles in a carrier fluid. Surfactants play an important role in this treatment (rheology, thixotropyetc.). It has been observed that particles with nanoscale size could be considered most effective for ER pastes15, 16.

On the basis of past studies, there are two types of ER fluids first which show property of increase in viscosity by applying the electric field regarded as positive ER fluid and second which show a decrease in viscosity on applying the electric field regarded as negative ER fluid. Positive ER fluids show strong polarization on applied electric field. Suspended particles form chain-like structures, parallel to the direction of the electric field between two electrodes. These chains begin to form thicker columns on intensifying the electric field. These modified structures of suspended particles give the fluid a high yield stress. On removing the applied electric field particles lose their strong polarization and return to free roaming condition. ER pastes have very fast response characteristics to the applied electric field. The rheology of the ER paste has been investigated by many researchers especially for conducting materials and solder pastes regarding solar cell applications like Burnside et al.(2000), Durairaj et al.(2004), Shiyong et al.(2008), Mallik et al.(2009) Amalu et al.(2011). It has been reported in their studies that the ER paste show shear thinning, thixotropic behavior and yield stress17, 18,19.

Our present study deals with the synthesis of monodisperse spherical silver nanoparticles using microemulsion method formed under high energy conditions. An aqueous solution of silver nitrate was taken as a source of silver ion, aqueous sodium borohydride solution used as reducing agent, 2- ethyl hexanol used as an organic phase for making oil in water microemulsion and sorbitanmonooleate (span-80) used as a capping agent. Transmission electron microscopy (TEM) and dynamic light scattering (DLS) techniques were used to find out the size, shape and particle size distribution of the synthesized silver nanoparticles. Crystalline nature of synthesized silver nanoparticles has been studied by X-ray diffraction analysis (XRD). Vacuum dried silver nanoparticles have been incorporated into fumed silica matrices using polyethylene glycol as carrier fluid using sonication and finally, uniform mixing was ensured by high-pressure homogenization in order to obtain a homogeneous electrorheological paste.

Materials and Method

A microemulsion method is developed for the synthesis of monodisperse surfactant capped spherical silver nanoparticles under optimized experimental conditions. The silver nitrate (≥99.0%, AgNO3), sodium borohydride (≥99.0%, NaBH4), Span-80 (non-ionic surfactant, HLB= 4.3) and 2-ethyl hexanol ((≥99.6%) were purchased from Sigma-Aldrich chemicals respectively. All chemicals were used as such without any further purification. Millipore water was used for the preparation of all sample solutions during synthesis. Fumed silica (0.007 µm, surface area=395 m2/g±25m2/g), polyethylene glycol-200 and terathane-1400 were directly purchased from Sigma-Aldrich chemicals for making ER paste.

Synthesis of Silver Nanoparticles

Synthesis of monodisperse spherical silver nanoparticles is performed by carrying out the reduction of an aqueous solution of silver nitrate with aqueous sodium borohydride solution. In our study, span-80 capped spherical monodisperse silver nanoparticles were synthesized by forming a microemulsion system under high energy conditions20. Here microemulsion is formed by mixing 250 ml of 0.08M aqueous silver nitrate solution (aqueous phase), 25ml of 2-ethyl hexanol (oil phase) and 2.5 ml span-80 as a surfactant. A high-speed homogenizer, IKA T25 digital ultra turrax was used to homogenize all components at a speed of 22000 rpm in a vessel and temperature is maintained constant at 40°C. 0.24M aqueous solution of sodium borohydride was added dropwise (2-3 drop/sec.) in the reaction mixture with high shear mixing till the whole silver ions get precipitated. With the addition of sodium borohydride, a spontaneous reaction occurred due to exothermic nature of reduction reaction. Formation of silver nanoparticles is revealed by the appearance of black colloidal suspension. The silver nanoparticles were collected by vacuum filtration using Millipore X11504705 filtration setup. The nanoparticles were given hot water and acetone wash to remove unwanted inorganic, organic impurities and water present along with silver nanoparticles.

Characterization of Silver Nanoparticles

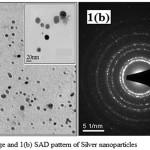

Silver nanoparticles prepared as above were characterized for their surface morphology along with SAD (selected area diffraction) pattern by TEM analysis by FEI Tecnai- G2 F20 (X-TWIN) transmission electron microscope using Cu-grid 200 mesh (Ted Pella INC.). Figure 1(a) and 1(b) shows TEM image and SAD pattern of synthesized silver nanoparticles (inset in figure 1(a) shows a high-resolution image of the same grid). The average particle diameter was found between 10-20nm and perfect crystalline nature was observed in the SAD pattern.

|

Figure 1a: TEM image and 1(b) SAD pattern of silver nanoparticles |

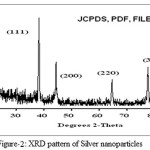

X-ray diffraction analysis is done by X-ray diffractometer, model ISO Debyeflex- 2002. XRD pattern of the synthesized silver nanoparticles is shown in figure.2. The X-ray powder diffraction was performed with Cu Kα radiation source (λ= 1.54184 A°) in 2-theta ranging from 10° to 100° (speed of scan 3°/min).The Bragg’s reflections observed here at 2-theta values of 38.115, 44.229, 64.443, 77.397 and 81.541 represent [111], [200], [220], [311] and [222] crystallographic planes respectively; which explain the formation of Ag nanocrystals with face- centered cubic (FCC) structure. The peaks obtained were in accordance with JCPDS file no. 04-0783. The absence of any other peaks indicates the purity of silver nanoparticles.

|

Figure 2: XRD pattern of silver nanoparticles |

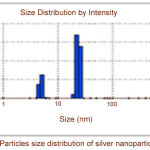

Particle size distribution is studied by Malvern Zeta sizer ZS-90 instrument. Figure-3 shows particle size distribution of synthesized silver nanoparticles. The average particle diameter was found ≥20nm, which is so because light scattering measurements report hydrodynamic diameter rather than actual diameter.

|

Figure 3: Particles size distribution of silver nanoparticles |

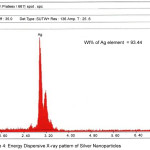

The elemental composition is determined by Energy dispersive X-ray analysis using Carl Zeiss EVO 50 LVSEM scanning electron microscope. The spot analysis of prepared stub shows 93.44 wt% abundance of synthesized silver nanoparticles.

|

Figure 4: Energy Dispersive X-ray pattern of Silver Nanoparticles |

Preparation of ER paste

Silver nanoparticles were vacuum dried before incorporation into fumed silica matrices. Ultrasonic processor (Vibracell Model VCX 750, Sonics & Materials INC, USA) was used for uniform dispersion of 2% fumed silica in 25 ml PEG 200. The process of sonication was carried out for two hours to get a homogenized solution of fumed silica with frequent cooling. Different amount of silver nanoparticles (10%, 20%, and 30%) were mixed directly to homogenized silica solution with continuous sonication for further one hour to get the different composition of ER paste. A small amount of terathane-1400 (0.5%) was used as an additive in preparing all samples. Finally, different samples of ER paste were subjected to high-pressure homogenization at 20,000-25,000 Psi under N2 gas atmosphere using Emulsiflex-C3 homogenizer (Avestin INC, Canada) to get homogeneous ER paste.

Results and Discussion

Electro-Rheological Analysis of ER Paste

The prepared samples of ER paste were subjected to rheological analysis by using Physica MCR rheometer (Anton Paar INC. Germany) having an electro-rheological device (ERD) to control the applied electric field. The diameter of parallel plate used for the whole experiment was 20 mm. During all the experiments the measuring gap between measuring device and measuring plate was adjusted to 1mm. A constant pressure of 5 bars was maintained throughout the experiment for air bearings of the rheometer by an auto-cut compressor. The applied electric field had a direction perpendicular to the measuring plate. The temperature was controlled during experiments by using a chiller (Viscotherm VT 2, Anton Paar, Germany). During experiments, calibration of rheometer was performed periodically to ensure accuracy and repeatability of the results.

Three samples (a), (b) and (c), of ER paste, were prepared by incorporating 10%, 20% and 30% by weight of the synthesized silver nanoparticles, respectively into fumed silica matrices using PEG- 200 as carrier fluid and terathane-1400 as an additive for avoiding chances of sedimentation.

Effect of Electric Field on the ER Paste

Effect of applied electric field on viscosities of samples (a), (b) and (c) have been studied under constant shear rate ranging from 0.0001 to 1.0 s-1, which is shown in figures-5 (a),5(b) and 5(c). It has been observed that no pronounced change in viscosities occur at a constant shear rate of 0.1 as well as 1.0 s-1 for all samples. A remarkable increase in viscosity at shear rate of 0.0001 s-1 is observed on increasing voltage for all samples. Sample (b) has shown approximately similar behavior towards increase in viscosity at shear rate ranging from 0.01 to 0.0001 s-1 on increasing applied voltage. At some intermediate concentration of silver nanoparticles this type of response may be observed, where polarization of nanoparticles is not very much influenced by applied electric field due to relatively weak bridging between nanoparticles. The dielectric breakdown for samples (a), (b) and (c) were observed at 1100V, 2000V and 3000V, respectively. It is observed from ER analysis that silver nanoparticles at higher concentration were strongly polarized with the applied electric field and tend to oscillate in a gap, interfacial polarization transfer charge from one electrode to another and thus creating high-frequency elasticity and viscosity of a suspension. Our synthesized silver nanoparticles have shown strong bridging phenomenon with increased concentration. A higher solid phase concentration of silver nanoparticles, a high increase in viscosity is observed at a relatively low shear rate (0.0001 s-1), on applying the electric field.

|

Figure 5a: Behavior of sample (a) w. r. t viscosity vs voltage under increasing constant shear rate ranging from 0.0001 to 1.0 |

|

Figure 5b: Behavior of sample (b) w. r. t viscosity vs voltage under constant shear rate ranging from 0.0001 to 1.0

|

|

Figure 5c: Behavior of sample (c) w. r. t viscosity vs voltage under constant shear rate ranging from 0.0001 to 1.0 |

Effect of Electric Field on Dynamic Yield Stress as A Function of Shear Rate of ER Paste

Effect of electric field on yield stress as a function of shear rate for samples (a), (b) and (c) is shown in figure-6(a), 6(b) and 6(c), respectively. All the samples were studied with common shear rate range from 0 to 1 s-1 under different applied electric field below their dielectric breakdown limit. Sample (c) has shown highest dynamic yield stress of about 1.5 kPa at 2800V which measure the good strength of the structure formed by the application of the applied voltage. At relatively higher shear rate thixotropic effect is observed for all samples, which might be due to aggregation of suspended silver nanoparticles caused by attraction forces like Van der Waals and repulsive forces due to the steric and electrostatic effect on the nanoparticles. These forces prevent nanoparticles that are suspended in the carrier fluid, from approaching closer and form a weak physical bond. When ER paste is sheared, these weak bonds are broken causing breakdown of the network.

|

Figure 6a: Behavior of sample (a) w.r.t. shear stress vs shear rate under increasing applied voltage ranging from 100V to 900V |

|

Figure 6b: Behavior of sample (a) w.r.t. shear stress vs shear rate under increasing applied voltage ranging from 400V to 1800V |

|

Figure 6c: Behavior of sample (a) w.r.t. shear stress vs shear rate under increasing applied voltage ranging from 400V to 2800V |

Conclusion

Silver nanoparticles were successfully synthesized by using novel microemulsion system using high energy conditions. The prepared novel microemulsion system is composed of aqueous silver nitrate solution as the aqueous phase, 2-ethyl hexanol as organic phase and sorbitanmonooleate (span-80ionics) as the capping agent. An aqueous solution of sodium borohydride was used as reducing agent. The synthesized spherical silver nanoparticles were almost monodisperse with average particle diameter 10-20 nm. A good crystalline pattern and a high particle density obtained in X-ray diffraction and energy dispersive X-ray analysis respectively, made silver nanoparticles suitable for preparation of ER paste. Three samples of ER paste were prepared by incorporating three different amounts of silver nanoparticles into fumed silica matrices using poly-ethylene glycol as the carrier fluid and terathane-1400 as an additive. Electrorheological analysis of ER paste revealed good consistency with respect to viscosity vs. voltage studies. It was found that on increasing nanoparticles concentration, an increase in viscosity is more pronounced along with their dielectric breakdown limit at the lowest shear rate. Moreover, ER paste with a high concentration of nanoparticles showed highest dynamic yield point of 1.5 kPa at 2800V when studied under shear rate ranging from 0.0 to1.0 s-1. ER paste containing lowest concentration of silver nanoparticles showed some shear thickening behavior whereas other two sample showed shear thinning behavior when studied under shear rate ranging from 0.0 to1.0 s-1. Overall reasonably high ER effect is achieved with silver nanoparticles due to their much higher surface area reflected in higher surface polarization.

Acknowledgments

The authors are thankful to IIT, Kanpur and F&L Division (DMSRDE) for the support in the characterization of the samples.

References

- Sobczak-Kupiec, A.; Malina, D.; Wzorek, Z.; Zimowska, M. Micro and Nano Letters.2011, 6, 656-660

CrossRef - Solanki, J. N.; Murthy, Z.V. P. Colloid and Surfaces A: Physicochemical Engineering Aspects. 2010,359, 31-38

CrossRef - Ramaswamy, V.; Vimalathithan, R.M.; Ponnusamy, V. Advances in Applied Science Research. 2010,1, 197

- Song, K. C.; Lee, S. M.; Park, T. S.; Lee, B. S. Korean Journal of Chemical Engineering. 2009,26, 153-155

CrossRef - Goia, D.V.; Matijevic, E.; New Journal of Chemistry.1998,98, 1203-1215

CrossRef - Zhang, W.; Qiao, X.; Qiu, X. Journal of Materials Science. 2009,44, 1076-1081

CrossRef - Rai, M.; Yadav, A.; gade, A. Biotechnology Advances. 2009, 27, 76-83

CrossRef - Nourafkan, E.; Alamdari, A. Journal of Industrial and Engineering Chemistry. 2014, 20, 3639–3645

CrossRef - Khadzhiev, Salambek N.; Kadiev, Khusain M.; Yampolskaya, Galina P.; Kadieva, MalkanKh. Advances in Colloid and Interface Science. 2013, 197–198, 132–145

CrossRef - McClements, DJ.; Li, Y. Advances in Colloid and Interface Science. 2010, 159, 213-228

CrossRef - Bilbao Sainz, C.; AvenaBustillos, RJ.; Wood, DF.; Williams, TG.; Mchugh, TH. Journal of Agricultural and Food Chemistry. 2010,58, 11932-11938

- Jahanzad, F.; Josephides, D.; Mansourian, A.; Sajjadi, S. Industrial and Engineering Chemistry Research.2010,49, 7631-7637

CrossRef - Katiyar, A.; Singh, A. N.; Shukla, P.; Nandi, T. Powder Technology. 2012, 224, 86-89

CrossRef - Gawade, S.S.; Jadhav, A.A. International Journal of Engineering Research and Technology.2012, 1, 10

- Davis, L. C. Journal of Applied Physics. 1992, 72, 1334-1340

CrossRef - Wen, W. J.; Huang, X. X.; Yang, S. H.; Lu, K. Q.; Sheng, P. Nat. Mater. 2003, 2, 727-730

CrossRef - Alias, R.; Sabrina, M. INTECH Open Acess Publisher. 2012

- Hao, T. Advances in Colloid and Interface Science. 2002, 97, 1-35

CrossRef - Hao, T. Amsterdam: Elsevier, 2005, 1, 561

- Shukla, P.; Nandi, T.; Singh, R.P. Oriental Journal of Chemistry.2016, 32, 2947-2955

CrossRef

This work is licensed under a Creative Commons Attribution 4.0 International License.