Prediction of Flow Behavior of Crude Oil-in-Water Emulsion through the Pipe by Using Rheological Properties

Vahid Hoshyargar, Azam Marjani*, Farzad Fadaei and Saeed Shirazian

Islamic Azad University, Arak Branch,Department of Chemistry, Arak, Iran.

Corresponding author: E-mail: a-marjani@iau-arak.ac.ir

Heavy and extra heavy crude oils are forming tremendous part of world crudes (about 40%). There are some problems limiting accessibility as a galore hydrocarbon source. One of limiting process is transportation which consumes very huge amount of energy due to their high viscosity. So, if there were a simple, stable, practicable in each situation and environmental friendly solution, these hydrocarbon sources could be used. Almost all over the world, the most common method for transportation of crude oil is being transported by pipeline from the production site to refineries or ports. Of course, pipeline transportation is very expensive and sometimes impossible because of heavy crude’s low mobility and high viscosity. The fact of an increase in world energy demand and the decline of conventional oils make heavy crude oils representing a relatively high hydrocarbons resource for use in future. Several methods have traditionally been proposed to enhance the mobility of heavy crudes and described here.

KEYWORDS:Emulsion; Heavy Crude Oil; Viscosity Reduction; Pressure Gradient

Download this article as:| Copy the following to cite this article: Hoshyargar V, Marjani A, Fadaei F, Shirazian S. Prediction of Flow Behavior of Crude Oil-in-Water Emulsion through the Pipe by Using Rheological Properties. Orient J Chem 2012;28(1). |

| Copy the following to cite this URL: Hoshyargar V, Marjani A, Fadaei F, Shirazian S. Prediction of Flow Behavior of Crude Oil-in-Water Emulsion through the Pipe by Using Rheological Properties. Orient J Chem 2012;28(1). Available from: http://www.orientjchem.org/?p=23762 |

Introduction

Heavy and extra heavy crude oils methods of transportation have a main challenge with their high viscosity. From 1975 to 2000, global demand for crude oil had growth rate about 1% average. “Emerging Countries” like China and India changed this stable growth in the first years of the 21st century due to their dynamic economies resulted in a remarkable 1.8% global growth in demand for crude oil in 2009 (IEA, 2010). Some important studies suggest that huge amount of the world’s energy requirements would be supplied from fossil fuels such as petroleum, natural gas and coal (IEA, 2008). As a result, crudes which was not reasonable to be recovered so far, would be important due to limited amount of available crudes. International Energy Agency (IEA) estimates, heavy oil represents at least 50% of the recoverable oil resources of the world. Heavy oil is a petroleum product with the density between 10 and 20 oAPI (density of conventional crudes are ranging between 38 and 40 API). If the density is lower than 10 oAPI it is considered as extra heavy oil if the viscosity is less than 10000 cP. Otherwise, it is called as bitumen which is denser than water (The difference refers to the production technology) (See fig.1). Production, transportation and refining of heavy crudes were frequently done because they are such highly viscous fluid with complex composition, so it would not be reasonable to process [1-3].

![Figure 1: Heavy, extra heavy and bitumen vs. viscosity and oAPI [5].](http://www.orientjchem.org/wp-content/uploads/2012/03/Vol28_Iss1_Vah_Pre_Fig1-150x150.jpg) |

Figure 1: Heavy, extra heavy and bitumen vs. viscosity and oAPI [5]. |

According to high amount of hydrocarbon content, methods such as heating, lubricating, upgrading, core annulus flow and emulsification come to resolve foregoing problem. As some examples Alberta, Orinoco Belt, Gulf of Mexico and Northeastern China could be noted for production of heavy crude oil as growing interests in the use of non-conventional heavy and extra heavy oil resources to produce fuels and petrochemicals [1-5].

The process of heavy oil to produce energy represents significant challenges that require significant development in technologies. Transportation of heavy and extra-heavy crude oil causes many difficulties in operation that make it practically uneconomic. However, the low mobility of heavy and extra heavy crude oils makes transportation difficult through pipelines -which it is due to wax and asphaltene deposition on pipeline wall surfaces- Beside the noted examples in above, Japan and USA, with growing energy demands; promote their refining industries to handle such crudes. Since, heavy and extra heavy oil are enough cheaper than conventional one, the refining benefits can be much more. Transporting crudes with pipeline is the most common and economical method for transportation of crude oils and also derived products. Still, one of the technological objects regarding the access of extra heavy oil to energy markets is the problem of pipeline transportation [5-8].

The method of emulsification seems to be more compatible by introducing asphaltene as natural surfactant [4]. It should be considered that the rheology of emulsions is not completely known and basically its knowledge is important to characterize the rheological behavior of oil-in-water emulsions. Such knowledge is also important, whether during probable feasibility study or designing the transporting pipeline.

Emulsions are dispersion of an immiscible liquid (dispersed phase) in another liquid (continuous phase). They are classified generally in 3 cases of Oil-in-Water (abbreviated in O/W), Water-in-Oil (abbreviated in W/O) and complex (multiple) emulsions. Multiple emulsions have droplets of continuous phase within droplets of dispersed phase such as Water-in-Oil-in-Water (abbreviated in W/O/W), (See Fig.2).

![Figure 2: Emulsion types: a) W/O b) O/W c) Multiple emulsion, W/O/W [8].](http://www.orientjchem.org/wp-content/uploads/2012/03/Vol28_Iss1_Vah_Pre_Fig2-150x150.jpg) |

Figure 2: Emulsion types: a) W/O b) O/W c) Multiple emulsion, W/O/W [8]. |

The most important part of an emulsion is the emulsifier which is usually expensive enough to affect the economy of emulsification process. Emulsifiers are molecules consist of a hydrophill and lipophill group(s) which allows such molecules enter in both water phase and oil phase. It is adsorbed at Oil/Water interface and keeps both phases next to each other by reducing interfacial tension. Fortunately the emulsifier is available in heavy crude oil itself. The components that cause high viscosity of crudes –asphaltenes– help us in producing a stable emulsion.

The rheology of emulsion is affected by several factors. The most important are: Volume fraction of dispersed phase (f), Temperature, Interfacial Tension and Droplet size and its distribution [3]. Increasing volume fraction causes droplets to be more compact, so increases the viscosity as a result of more friction between droplets. Orientation of droplets, viscosity of each phase, energy barrier and interfacial tension are influenced by temperature that characterizes rheological properties of emulsion. Low or high interfacial tension representing the energy needed for rupturing the drops and the dis/similarity to a hard sphere [1]. Finally, an increment in the droplet size at a certain volume fraction, included with decreasing surface per unit volume –which means decreasing friction– and lowering viscosity [9-10].

Materials and method

In this research, alkaline water-based solution is used to activate asphaltene content materials in crude oil as a natural surfactant. Alkaline solutions have been prepared by solving sodium carbonate (Na2CO3) in tap water. West-paydar crude oil which is located in heavy crude oil classification (due to its asphaltene content) was used as oil phase. The homogenizer PT-1200C produced by Polytron was used to disperse different amount of crude into water phase to yield 50 ml O/W emulsions in 2:30~3:00 min at 10’000~13’000 rpm.

Results and discussion

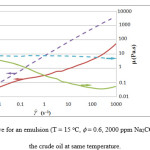

The results of rheometery are flow curves which representing tension ( ) vs. shear rate ( ). Each sample would experience low (0.001 s–1) to high shear rate (1000 s–1) and vice versa. It causes the irregular flocculation to be broken and makes the emulsion take a shear rate history. Fig.3 demonstrates both the forward and backward flow curve (the properties of sample are given in caption). Fig. 3 also indicates the flow curve for crude at same temperature. Fig 3 has a secondary axis to show apparent viscosity.

|

Figure 3: Flow curve for an emulsion (T = 15 oC, f = 0.6, 2000 ppm Na2CO3, 10000 rpm) and the crude oil at same temperature Click here to View figure |

Each flow curves is fitted to the Herschel-Bulkely model and the parameters are listed in table 1 while Herschel-Bulkely model is represented by:

![]()

Table 1: Herschel-Bulkely parameter for emulsion and crude at 15 oC

|

|

K |

n |

y |

MRSE |

|

Crude oil |

8.013053 |

0.947999 |

0 |

2.80E-02 |

|

Emulsion |

0.307375 |

0.545537 |

0.014541 |

0.008631 |

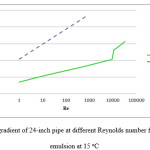

The pressure gradient of pipeline could be estimate base on correlation of turbulent and laminar flow of Herschel-Bulkely fluid [6]. Fig. 4 shows calculation of pressure gradient for a 24-inch pipe with the velocity of 0.015 to 3.5 m/s for crude oil and above emulsion.

|

Figure 4: Pressure gradient of 24-inch pipe at different Reynolds number for crude and above emulsion at 15 oC |

Conclusions

This emulsion’s rheological behavior is explained well by Herschel-Bulkely model. It is obvious that emulsification could help high pressure drop to moderately low one by reduction of almost 99% per unit length of pipeline. Comparison made between the results of this research and that of [7-9] that was such an experimental pressure gradient measurement, indicates good consistency.

References

- Saiki Y. and Prestidge C. A., “Droplet deformability and emulsion rheology: steady and dynamic behavior”, Korea-Australia Rheology Journal, 17(4)191-198. , 2005.

- Mason T. G., “New fundamental concept in emulsion rheology”, Current Openion in Colloid & Interface Scienec, 4, 231-238, 1999.

- Hasan S. W., Ghannam M. T. and Esmail N., “Heavy crude oil viscosity reduction and rheology for pipeline transportation”, Fuel, 89, 1095-1100, 2010.

- Langevin D., Poteau S., Henaut I. and Argillier J. F., “Crude oil transportation and their application to heavy oil transportation”, Oil & Gas Science and Technology, 59, 511-521, 2004.

- Sanier A., Henaut I. and Argillier J. F., “Pipeline transportation of heavy oil, a strategic, economic and technological challenge” , Oil & Gas Science and Technology, 5, 455-466, 2004.

- Malin M. R., “Turbulent pipe flow of herschel-bulkley fluids”, Int. Comm. Heat Mass Transfer, 25, 3, 321-330, 1998.

- Martínez-Palou R., Lourdes Mosqueira M., Zapata-Rendón B., Mar-Juárez E., Bernal-Huicochea C., Clavel-López J.C., Aburto J, “Transportation of heavy and extra-heavy crude oil by pipeline: A review”, Petroleum Science and Engineering, 75, 274–282, 2011.

- Hoshyargar V., “Rheology of Crude Oil-in-Water Emulsion”, Msc Thesis, department of chemical engineering, IUST, 2011.

- M. Yaghi B., Al-bemani A., “Heavy Crude Oil Viscosity Reduction for Pipeline Transportation”, Energy Source, 24:93-102, 2002.

- Shirazian, S., A. Moghadassi, and S. Moradi, Numerical simulation of mass transfer in gas-liquid hollow fiber membrane contactors for laminar flow conditions. Simulation Modelling Practice and Theory, 2009. 17 (4): p. 708-718.

This work is licensed under a Creative Commons Attribution 4.0 International License.